|

|||||||||||||||||||||||||||||||||||||||

|

Interface devices of the product family DC-HI-NET adapt

your whole measurement and interface variety to one single interface. Our simple but

powerful protocol is supported by all leading software packages for quality assurance and

production control on PC´s and workstations. Independent of measurement devices and

software suppliers you select your appropriate solution for process control. |

|

| DC-HI-NET connects all measurement devices and data sources with interfaces like: | |

|

|

| via one single standardized interface to your software for | |

|

|

| on PC´s and Workstations. | |

| DC-HI-NET is an interface device with own "intelligence" which is connected to the computer via the serial interface. With DC-HI-NET you get an interference-proof solution, easy to install and to extend. Further software adaptations and host configurations are not required. | |

|

|

|

||

|

||||

|

|

|

The measurement instruments are connected to the interface device via

standard cables, which are typically provided by the measurement equipment manufacturer.

You reduce costs and protect yourself against confusions. Our well documented, easy-to-use driver library (DLL) allows data capture into your Microsoft Windows applications. Event- controlled measurement data capture (with manual or foot switch contacts) and channel arithmetics facilitate multipoint measurement and simple transfer of the results into Microsoft Excel. The device- independent DC-HI-NET Protocol provides comfortable functions. Simple commands allow you to pre-process the data. This removes processing load from the host system - the real time capabilities improve substantially. Features like the automatic measurement device recognition and free configuration protect you from inconvenient burocratic and configuration tasks. The DC-HI-NET Operating System carries out the following functions:

|

| DC-HI-NET – Universal interface for quality assurance and measurement. |

|

The modular, extendable interface system for all measurement instruments |

|

Connection of measurement devices via the keyboard interface - without any software adaptations |

|

Pre-configured, cost efficient solution for single locations, optionally in protection class IP65 |

|

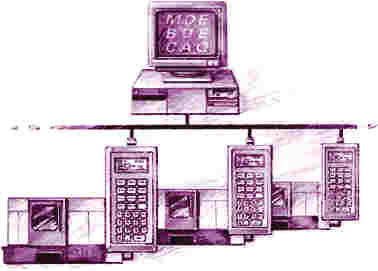

Data capture via field bus with the compact industrial terminal with measurement interfaces |

|

Are you interested in further information ? Please contact us ! |

|||